Wir sind FlowLogiX

Wir sind ein junges StartUp aus Dresden, mitten im SiliconSaxony und unsere Leidenschaft gilt allen Arten von automatisierten Transportsystemen. Die FlowLogiX GmbH ist eine Ausgründung aus dem Institut für Technische Logistik an der TU Dresden und uns verbindet die Passion für Software und Dienstleistungen um die Intralogistikprobleme unserer Kunden zu lösen und sie zu unterstützten in einer Welt von Digitalisierung, IOT und Industrie 4.0.

Wir erschaffen

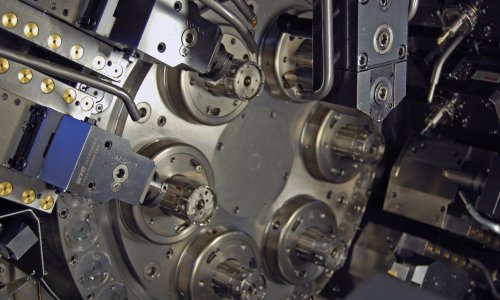

Wir erschaffen den Digital-Twin für alle Arten automatisierter Transportsysteme - egal ob schienengeführt oder freifahrend, an der Decke oder auf dem Boden. Unser FlowLogiX MMS bietet einen durchgängigen Workflow von der Planung bis zum täglichen Betrieb eines AMHS mit Live-Visualisierung, Analyse, Anpassung und Simulation. Zudem nutzen wir sie zur Beratung bei der Gestaltung, Auslegung und Optimierung von Transportsystemen.

Wir bei FlowLogiX erstellen anspruchvolle Software für unterschiedlichste Anwendungsfälle und können Sie bei der Entwicklung Ihres Datenmodells oder Ihrer datengetriebenen Anwendung unterstützen und verfügen über umfassende Kenntnisse über das Erstellen von Simulationsmodellen und -anwendungen.

Unsere Kunden

Unsere Leidenschaft gilt allen automatisierten Transportsystemen. Besonders fasziniert sind wir jedoch von den AMHS (Automated Material Handling Systems) moderner Halbleiterfabriken. Ob schienengebundenes Deckenfördersystem (OHT – Overhead Hoist Transport) oder Förderbänder (Conveyor System) – der gesamte Prozess bietet aus unserer Sicht vielfältige Optimierungspotenziale: von der Auftragsentstehung im MES (Material Execution System) über die Weiterleitung an das Transportsystem mittels Material Control System (MCS) bis hin zum physischen Transport. Bisher konnten wir an jeder Stelle dieses Prozesses Verbesserungen identifizieren und erfolgreich umsetzen. Dabei greifen wir auf folgende (teils hauseigene) Tools zurück:

- History Player

- Erstellung und Nachbildung von Dispatch-Regeln im APF

- Algorithmenbasierte Optimierung von Routing und Leerfahrzeugverteilung

- Statische Simulation

- Dynamische Simulation

Überzeugen Sie sich von unserem Fachwissen – wir helfen auch Ihnen gerne weiter.

News

Die FlowLogiX GmbH freut sich, mit dem Vorhaben

„Vorbereitung der Implementierung einer Erweiterung und Verallgemeinerung von Transportsystemen in die bestehende Monitoring and Maintenance Suite der FlowLogiX GmbH - Fokus Conveyor-Systeme“

Teil des ESF Plus - MINT-Fachkräfteprogramms im Freistaat Sachsen zu sein. Zur Umsetzung des Vorhabens konnte mit Hilfe der Förderung aus dem Europäischen Sozialfonds Plus (ESF Plus) im Freistaat Sachsen im Förderzeitraum 2021 – 2027 unser Team um eine Produktentwicklerin erweitert werden.

Im Rahmen des Projekts liegt das Ziel auf einer Erweiterung und Generalisierung der Monitoring and Maintenance Suite (MMS) zur Integration von Conveyor-Systemen und weiteren Transportsystemarten nach dem Overhead Hoist Transport (OHT)-Prinzip. Dies beinhaltet zudem die Analyse der bestehenden MMS und Identifikation von Erweiterungspotentialen. Darauf aufbauend wird ein Konzept zur Weiterentwicklung der MMS basierend auf neuesten wissenschaftlich-technischen Erkenntnissen bzgl. Datenauswertung, Datenhaltung und Datenvisualisierung erarbeitet. Es soll in diesem Zusammenhang ebenfalls die bestehende MMS auf Optimierungs- bzw. Innovationspotenzial untersucht werden. Ein in diesem Zusammenhang notwendiges Ziel ist ein Konzept zur Lokalisierung von Ladungsträgern bei unzureichender Datenlage in der beim Kunden vorgefundenen Ist-Situation.

Dieses Projekt steht im Einklang mit unseren Zielen, technologische Fortschritte voranzutreiben und unsere Wettbewerbsfähigkeit zu stärken.